POLYALK WP: Polymeric Waterproofing Coating

4.2 Stars Rating

| Material | Chemical |

| Brand | SUNANDA POLYALK WP |

| Style | Compact |

| Item Weight | 5 Kilograms |

| Item dimensions | 20 x 15 x 32 Centimeters |

- Application & Activity

- Features & Benefits

- User Guidelines

- Roof slabs – flat or sloping, chajjas, folded plate roofs, vaulted roofs, domes, etc.

- Flooring, external walls

- Sunk and non-sunk portions of bathrooms, toilets, balconies, etc.

- Overhead or underground water tanks and other large reservoirs

- Mortars for filling joints of C.I. or any other drainage pipes

- As a protective coating to RCC floorings, substructures against sulphate attacks

- It can be easily mixed with cement forming an impermeable co-matrix film

- Alkaline and compatible with concrete

- It does not facilitate carbonation

- It can be applied in moist and damp conditions, e.g., exteriors, and terraces in wet spells of monsoon

- It can be applied in underground and/or overhead water tanks almost immediately after emptying

- High flexural strength and extraordinary adhesion of the polymer

- It can be used as a base waterproofing coat on external walls, and after curing, it can receive SUNEXT 8

- Surface preparation of the surface to be waterproofing is very important.

- Scrub and clean the surface

- Remove laitance, dirt, paint, loose flakes, particles, foreign matter, etc.,

- For cleaning, you can use a vacuum cleaner, a high-pressure water jet, wet sandblasting, or wire brushing

- Ensure that the concrete surface possesses an open pore surface texture

- Repair any faulty concrete in the form of cracks, honeycombing, etc.

- Fill hairline cracks on plaster/mortar fill the same with POLYFILL AR as per specifications

- Remove all curing compounds and sealers

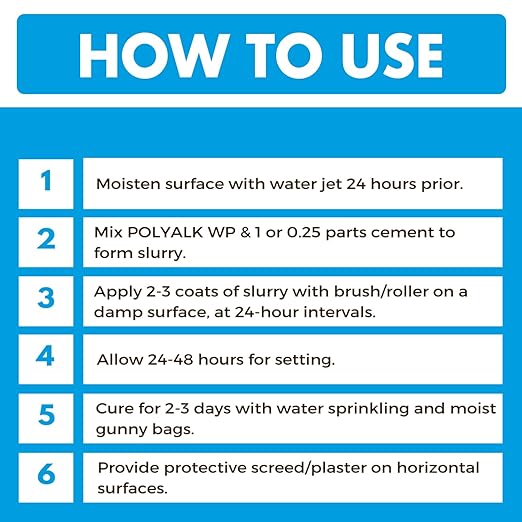

- Moisten the surface with a water jet 24 hours before applying POLYALK WP

- Mix 1 part of POLYALK WP and 1 or 1.25 parts of fresh white or grey cement

- Continuous hand-mixing to form a lump-free consistency may also be adequate

- Keep the mix continuously stirred

- Apply the slurry by brush/roller to the damp surface

- Apply two/three more coats of similar slurry at 24 hrs intervals

- Allow setting for 24-48 hours

- Cure the coating for 2-3 days by sprinkling water on the vertical surface (external walls) three times a day

- Use moist gunny bags on the horizontal surface (terraces, toilets, etc.)

- Provide a protective screed/plaster for flat surfaces on the POLYALK WP coating

- For external surfaces, provide a protective coating of SUNEXT 8

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

It has long lasting guarantee. Very high quality product must buy.

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

Frequently asked questions (FAQ)

Q. What are the different types of waterproofing coats?

There are different types of waterproofing coatings including acrylic elastomeric coatings, polyurethane coatings, polymer-cementitious coatings, epoxy coatings etc. Choosing the right type depends on your specific needs, surface material, budget, and skills. Always consult the manufacturer’s instructions and research before applying any waterproofing coat.

Q. What chemical is used for waterproofing?

Waterproofing chemicals come in many forms, but some widely used chemicals are acrylic polymers and polyurethanes. They can form flexible, durable membranes ideal for roofs and exposed surfaces. The best choice depends on the specific application and material being protected.

Q. Which waterproofing is best for the outside walls?

The best waterproofing for outside walls depends on your needs. Factors like budget, surface type, etc, should be considered. Elastomeric waterproofing is flexible for accommodating cracks and movement. Polymeric-cementitious waterproofing coatings are strong and durable and are great for smaller wet areas while being versatile and long-lasting.

Q. Is epoxy coating waterproofing?

Epoxy can be waterproof, but depends on type and application. Some epoxies offer excellent water resistance for floors, countertops, and specific surfaces. However, not all are designed for exposed walls or extreme water exposure. Choose specific waterproofing epoxies and ensure proper application for best results.

Q. What is PU coating?

PU coating, or polyurethane coating, is a type of resin used to make waterproofing coatings. It is known for its flexibility, and resistance to abrasion, chemicals, and water. This coating enhances material lifespan and is widely used in outdoor gear, furniture, and flooring for its robustness and aesthetic appeal.