Contents

SIZE OF THE CONCRETE REPAIR INDUSTRY IN INDIA:

In India, the concrete repair work market is not organized. Hence the precise numbers on annual price to owners/ public exchequer for fixing and defence and conditioning are not readily available.

Strengthened Concrete has been a product of choice and is the 2nd most utilized resource worldwide after water. The Indian Construction Industry is set to increase from US$ 428.1 billion today to US$ 563.4 billion in 2020(R¹).

Exponential development in Indian concrete construction over the previous 40 years has produced extremely sizeable demand and the market for repair services-related activities.

Damage to concrete happens due to ecological criteria; damages triggered to frameworks because of external firms, fundamental flaws in the concrete frameworks, and alteration in operation, which can occur subsequently. Almost all the concretes are made based on the architectural demand of each framework and need to be custom-made.

This concrete has to use neighbourhood products from plural sources having various high quality, which can be marginal. In some cases, the styles are not typical as well, as, at times, one has to work at a neck-breaking rate to create the outcome, which results in sped-up construction processes but may compromise quality at times.

The above aspects bring about malfunctioning and early distress check-in a structure. They have led to the climbing of a market likely to presume an identical industry to the new building sector. In India, this market/industry need to be arranged, though large and spread over all the nooks and corners of the subcontinent.

Yet, the size can be worked out by interpolation and projection. When interpolated with the distress and the health of stock over the previous 40 years, the yearly expense to proprietors for repair service, protection, and conditioning could be approximately between US$ 40 and 45 billion.

INDIAN REPAIR INDUSTRY SCENE AND WHY HAS THIS DETERIORATION HAPPENED?

- India is the second-largest producer of cement. For this reason, the overall stock of different structures is also extensive, a significant part of which requires repairs after an apparent call for help adhered to by their wellness analysis.

2. India has transitioned from 15 MPa to 60 MPa in the span of half a century as a basic pattern, though till two decades ago, prevailing stamina was 15-25 MPa. This means the stock of reduced-grade structures is a tradition of the past.

3. Low cover and also various other earlier wrong concrete techniques connected with chloride assault, as well as now carbonation, have worsened the scene.

4. Rapid urbanization and industrialization is enhancing carbonation attack in general.

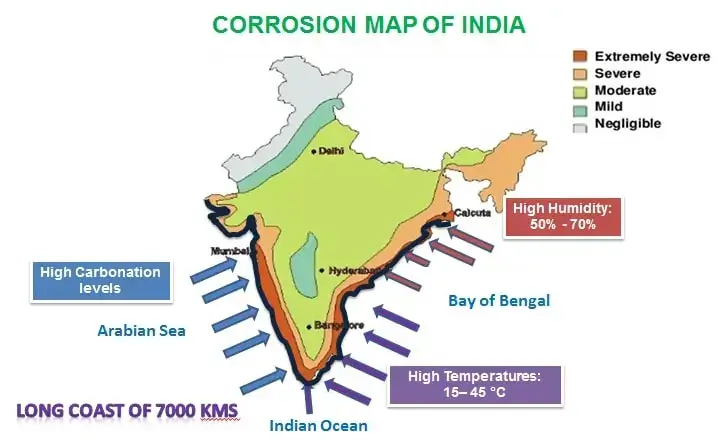

5. India is a heat nation with a long coast of 7000 kilometers, high humidity, and tropical rainfalls. 35000 sq m of coastal areas are under the continuous assault of airborne chlorides.

GENERAL CONCEPT OF CONCRETE REPAIR IN INDIA:

- To remove deteriorated loose concrete

- Expose corroded reinforcement

- Semblance of cleaning and removal of corrosion products on heavily corroded steel

- Use of rust removers

- Use of bonding agents

- Use of polymer mortars

- Use of protective coating

The rapid growth of the concrete repair work industry, as well as poor efficiency in the past 40 years, has resulted in highlighting several drawbacks and also the need for enhancements in:

Materials

- Design practices

- Installation procedures

- Contracting processes

- QA/QC procedures

- Education and allied several aspects

Regardless of difficulties, the development in concrete repair activity is continuous because usual man/client notifications indicate distress in the form of splits, delamination, failure, and even sudden collapse and also looks for urgent interest to allay his concerns concerning safety and security. Collapses at routine periods and life loss bring lots of visibility, hence the alarm system.

The vast stock of concrete in India is 10 years plus old. A lot of this concrete was site combined and without lots of controls. Usually, it is extra susceptible to carbonation, chloride attack, loss of alkalinity and assault of various other aggressive chemicals, and so on.

Today India is placing new concrete to the tune of approximately 1.75 – 2 billion m3/ per annum, which naturally requires being shielded. As against if we look at currently placed concrete in the previous half a century, it would certainly be 55 – 60 billion m3 which currently requires much security.

Longevity of Concrete Repairs:

The short life process of fixings raises questions on the expertise and recognition regarding the technological competencies of associated personnel and companies. The rebuilding of older frameworks is different from the basic norm. Hence frameworks are majorly fixed as well as sadly repaired.

Engineering pupils and engineers are not shown concrete or scientific research on steel corrosion with a unique focus on products. Repairs are not a science instructed in design schools. As a result, many locations remain “grey” because of a lack of official training, education, learning, discovery, “State-of-the-art” procedures, hands-on training, etc.

Unique repair work products like Polymers, Epoxies, Protective finishes, Nano Materials, etc., are not part of the academics of civil engineering pupils/ engineers. (Possibly not in other parts of the globe, likewise).

Performance of Repairs:

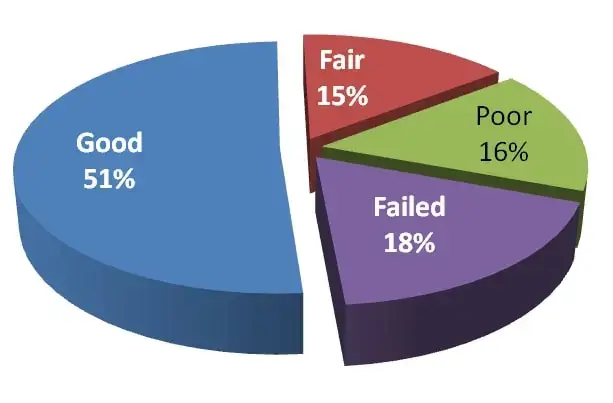

Among the most significant stock of concrete structures are with the U.S. Army Corps of Engineers, and also their experience is as under:

That suggests that even in a sophisticated country like the U.S.A., barely 50% of the repairs perform adequately, and the remaining fixings come under reasonable, foul, or fell short classification due to the issues in design, setup, materials, and also various other criteria.

What could be the success price of the fixings in India, and WHY? A Projection.

WHOLE LIFE COST & PERFORMANCE OF REPAIRS:

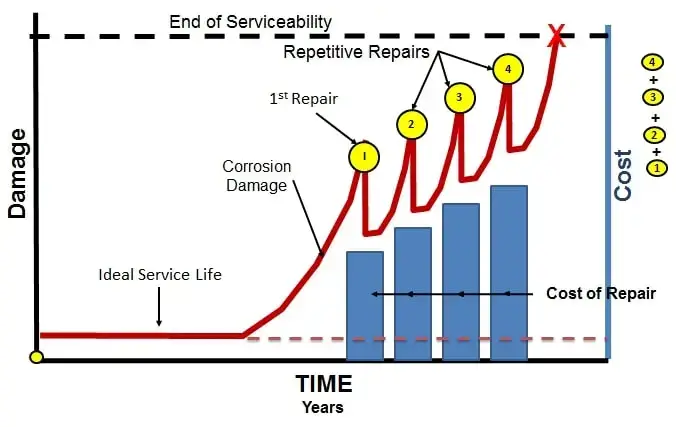

The analysis of re-repairs shown (Fig. 3) is as under:

However messy, fixings is a massive sector in India and qualities judicious interest to manage the gigantic loss to a nationwide wide range by preventing frequent failures. Concrete repair operations are extraordinarily delicate and also vital.

Various actions involved in repair services projects depend on the specifier’s understanding of degree and fancy. The specifications are often copied from one specifier/job to various others.

Therefore though repair work is planned to expand the service life, frameworks usually seem to fail too soon because of the incorrect technique of fixings and the absence of a defined obligation criterion. Trained personnel is needed, but commonly semi-skilled persons change trained ones, as a result of which the Client/job suffers– but awareness after the failure and also the loss is irreversible.

Promotions, like we will not bill or will undoubtedly charge only nominal fees– are not the approved standard, but trustful individuals are victims of this quackism. The demand is enormous, and there is always a brand-new victim/client at regular periodic intervals.

For this reason, a Technique exists to raise the liability of stake owners of the repair services market by understanding individual and collective duties.

Numerous procedures are needed in any repair work, depending on the kind and the level of damage.

| · Membranes, Sealants, Coatings | · Waterproofing |

| · Surface Preparation – Hydro/Shotblasting | · General Concrete Repairs |

| · Grouting/Crack Injection | · Concrete Placement |

| · Foundation Underpinning | · Formwork |

| · Vertical (High Rise) Repairs | · Steel Placement |

| · Gunniting/Shotcrete | · Post-Tensioning |

| · Underwater Repairs | · Cathodic Protection |

| · Industrial Floor Repairs |

Thus comes the demand for Expert Contractors with their duty specified.

At the same time, the problem of the obligations of all concerned, e.g., designers, contractors & government companies, is available in the picture. Private repair work is more minor in worth as compared to brand-new buildings.

For this reason, it will undoubtedly be hard for Federal government Authorities to give the authorizations and conclusion certifications for all these jobs due to the real-time outrageousness of sheer numbers for the equipment to deal with.

Nevertheless, it is imperative to make sure that Consulting Practicing Engineer is specially educated and accredited for repair work technology and methods as this is various scientific research of civil engineering which deals with material residential properties & behavior of the structure as a result of deterioration.

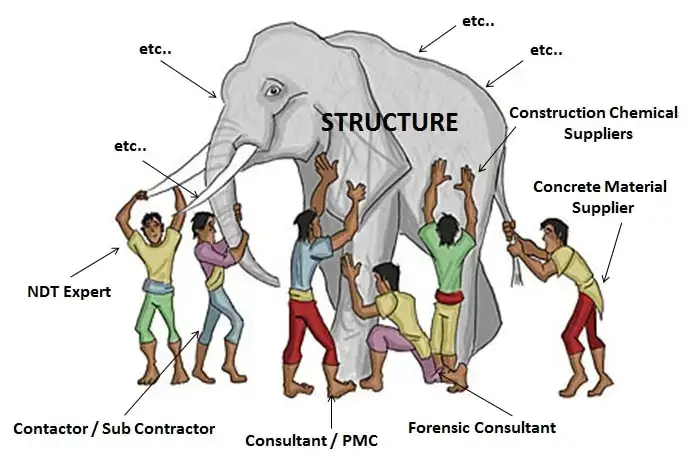

Special programs/ examinations/ qualification criteria must be exercised. This is an uncomplicated job, as abundant referral material is available locally and globally. Otherwise, without such unified treatment, every certified civil engineer will have to use numerous caps like NDT specialists, material professionals, corrosion specialists, etc. The story will undoubtedly become like an Elephant and also 6 Blinds.

In India, due to the unorganized nature of the market and out-of-date techniques of implementation, the performance would be still more minimal and can be as under as received in fig 4:

Individual repair service agreements are more minor in worth compared to new tasks; thus, multi-level guidance is challenging and uneconomical. For this reason, the final duty comes from the customer’s selected consulting engineer and the professional.

However, oftentimes the entire (365°) suggestion concerning logic, analysis, and QC specifications for the contract, both in authoritative and performance format, are not known to either the consultant or the specialist. This is more due to the diverse complexity of the subject as well as the lack of knowledge.

The rational treatment can be accomplished only by enhancing awareness and specifying the obligations of all the risk holders in the repair service sector.

There are numerous beneficiaries of the repair work industry.

| · Engineers | · Testing companies |

| · Architects | · Educators |

| · Contractors | · Researchers |

| · Equipment suppliers | · Lawyers etc. |

| · Material manufacturers |

Many worried risk holders in the industry remain in dire need of updating their skills, Modern understanding. At the same time, the private and synergistic responsibilities of the stake owners should also be well defined to boost life span, decrease costs, and lower disputes. Mere repairing responsibilities is inadequate, yet knowledge is imperative.

Then the market would enhance its rating card to get more than 20% effective with performances. e.g., as under.