The concrete floors in airports and other transport hubs are handling nonstop aircraft movement and heavy loads. PU concrete flooring meets these extreme demands with tough, low-maintenance durability. Designed for such critical operational areas, it withstands forklifts, ground support equipment, and continuous use.

Read on to discover how PU flooring keeps critical spaces like airports strong, safe, and operational under pressure.

Contents

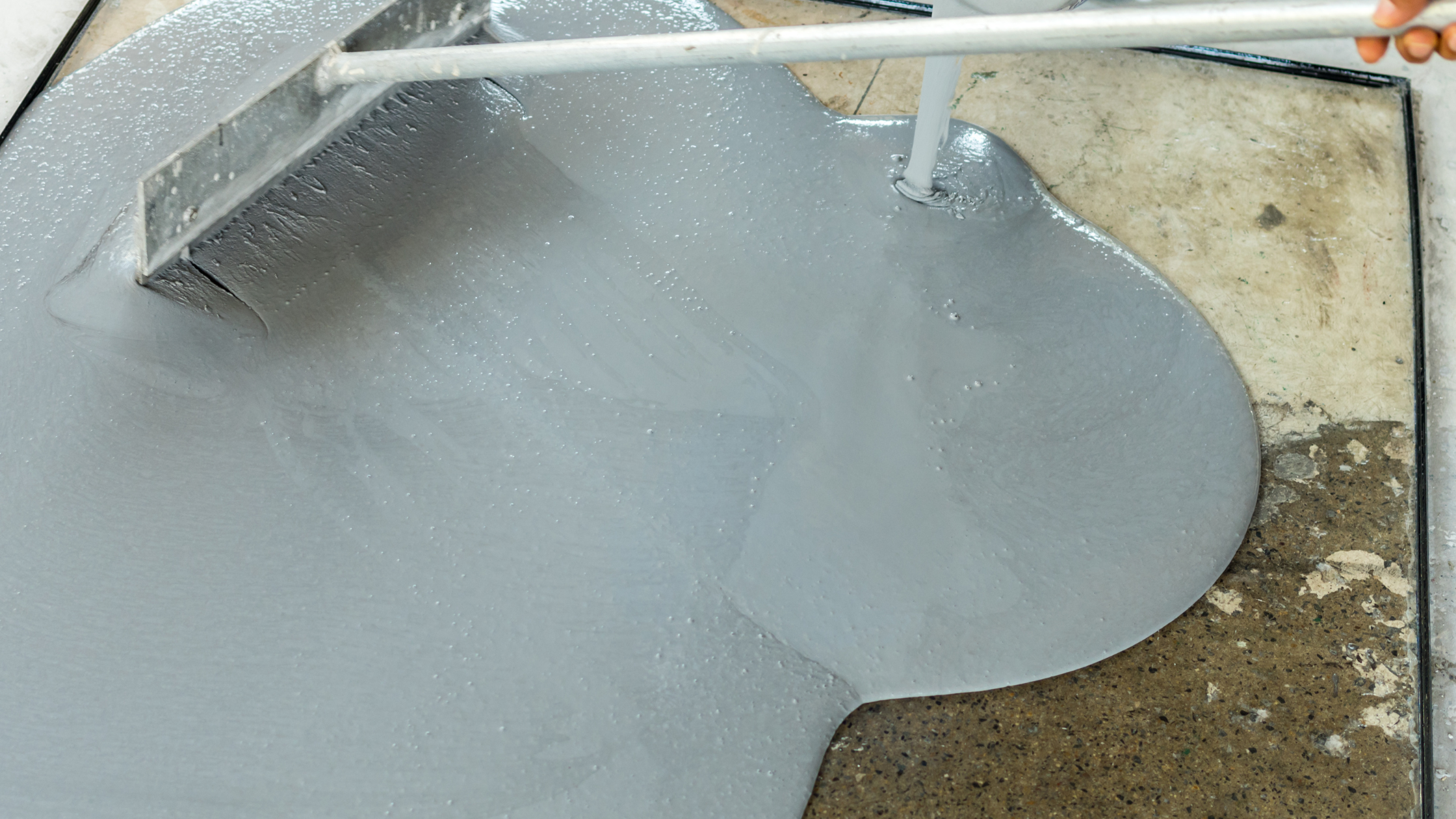

Why Is PU Concrete Flooring the Best for Airports?

Here are 5 reasons why you must choose PU flooring for airports and other high-traffic transport hubs.

Heavy Traffic and Load Resistance

PU concrete flooring is suited to handle heavy aircraft traffic, accommodate the heaviest equipment, from baggage trolleys to forklifts and service vehicles. The engineering is designed and meant to permit the heaviest loads found in these critical airport support zones.

Basically, this flooring can handle extreme pressure without buckling and allows operations to continue without costly downtimes.

Interested in how flooring technology protects other high-traffic spaces? Check out our guide on Car Parking Flooring in Commercial Spaces to discover the three must-know options that stand up to heavy vehicles and oil spills.

Abrasion and Impact Resistance

In aircraft hangars, warehouses, and other airport support zones, daily activities involve heavy carts, equipment collisions, and constant movement of machinery. Withstanding scratches, scuffs, and dents that heavy machines inflict is the specialty of PU concrete. It is designed to resist cracking when subjected to continuous impacts and load cycles over time.

Also, the flooring maintains excellent surface integrity, so that the smooth finish supports both functionality and a clean, professional appearance.

Safety and Compliance

PU concrete flooring offers a non-slip surface and is engineered to meet stringent airport safety standards and regulatory requirements. This ensures a safe working environment for staff handling heavy machinery and equipment. This slip-resistance is built into the flooring, not just an added topcoat, so the safety benefits remain consistent over time and with wear.

Smart Systems That Take Care of Themselves

PU concrete flooring systems are engineered to be smart, low-maintenance solutions built for demanding industrial use. Their long-lasting durability minimizes the need for frequent repairs, allowing terminals and transit stations to remain operational without disruptive closures.

The smooth, resilient surface is easy to clean, supporting stringent hygiene and maintenance standards. Plus, with fast installation times, PU floors can be upgraded or repaired swiftly. This reduces downtime and keeps busy transport hubs running smoothly.

Cost-Effective Solutions with Enduring Value

Airports and other transport hubs operate on tight budgets, and PU concrete flooring has great ROI. Its exceptional durability lowers life cycle costs by reducing the need for frequent repairs or replacements. This reliability makes operational expenses more predictable, allowing facility managers to budget with confidence. The long-lasting performance of PU floors ultimately improves return on investment.

If you are running an airport, you also need to think about complete waterproofing. Make sure your entire facility stays dry with our practical guide on Basement Waterproofing for Commercial Spaces, featuring expert tips on sump drains, polyurethane injections, HDPE membranes, and more.

Other Applications of PU Concrete Flooring

While airports and transit stations lend themselves well to PU flooring, it is also quite useful in:

- Industrial areas: Industries, including manufacturing, automotive, and warehousing, need floors that can withstand heavy machinery, chemical spills, or moisture.

- Commercial Settings: Shopping centres, event spaces and larger public areas can all benefit from having a functional, easy-to-maintain flooring option.

- Speciality Areas: Anti-static versions of PU concrete flooring are ideal for sensitive environments like electronics manufacturing, clean rooms, and laboratories.

Sunanda’s Polyurethane Flooring Solutions

SUNCRETE PU MF: Polyurethane-Concrete Flooring

- Easy application and fast curing

- Chemical & abrasion resistance for long-lasting durability

- Smooth surface that is easy to clean

- Color options to enhance the environment

SUNCRETE PU HF: Heavy-Duty Polyurethane-Concrete Flooring

- Quick & easy application with fast curing

- Chemical & abrasion resistance for tough environments

- Colour variety to fit any workspace

SUNCRETE PU AS: Anti-Static Polyurethane Flooring

- Impact & abrasion resistance for high-performance areas

- Smooth & hygienic finish for easy maintenance

- Chemical resistance and low odour for a safer installation

Why Is Sunanda a Smart Choice for PU Concrete Flooring?

Sunanda Global brings extensive expertise spanning more than 45 years to provide permanent PU concrete flooring systems. Our certification as India’s sole ISO 9001:2015 manufacturer ensures our superior quality. We offer tailored PU concrete flooring for various commercial and industrial needs. Moreover, you can expect full-cycle support from Sunanda, from consultation to installation.

We also dedicate 5% of our revenue toward Research and Development which focuses 60% on creating environmentally-friendly LEED-certified products. Our products are low-VOC, environmentally friendly options, suitable for sustainable projects.

Partner with Sunanda Global today for premium PU flooring solutions that cater to your industrial and commercial needs.