ELASTOROOF PU

ELASTOROOF PU is a single component, liquid-applied, moisture-cured, polyurethane elastomeric membrane for waterproofing and sealing various kinds of surfaces. The product cures to a rubber-like finish with excellent flexibility and chemical resistance properties.

WATCH THE VIDEO ON PU WATERPROOFING FOR THE LARGEST CRICKET STADIUM IN THE WORLD WITH ELASTOROOF PU

WATCH THE VIDEO ON PU WATERPROOFING FOR THE LARGEST CRICKET STADIUM IN THE WORLD WITH ELASTOROOF PU

Easy Application

No-Blending-Required(Ready To Use)

Non Toxic

700% Enhanced Elongation

Cold Applied

No Fire-torch required

High Performance

Save Time And Money

WATCH THE VIDEO ON PU WATERPROOFING FOR THE LARGEST CRICKET STADIUM IN THE WORLD WITH ELASTOROOF PU

Easy Application

No-Blending-Required(Ready To Use)

Non Toxic

700% Enhanced Elongation

Cold Applied

No Fire-torch required

High Performance

Save Time And Money

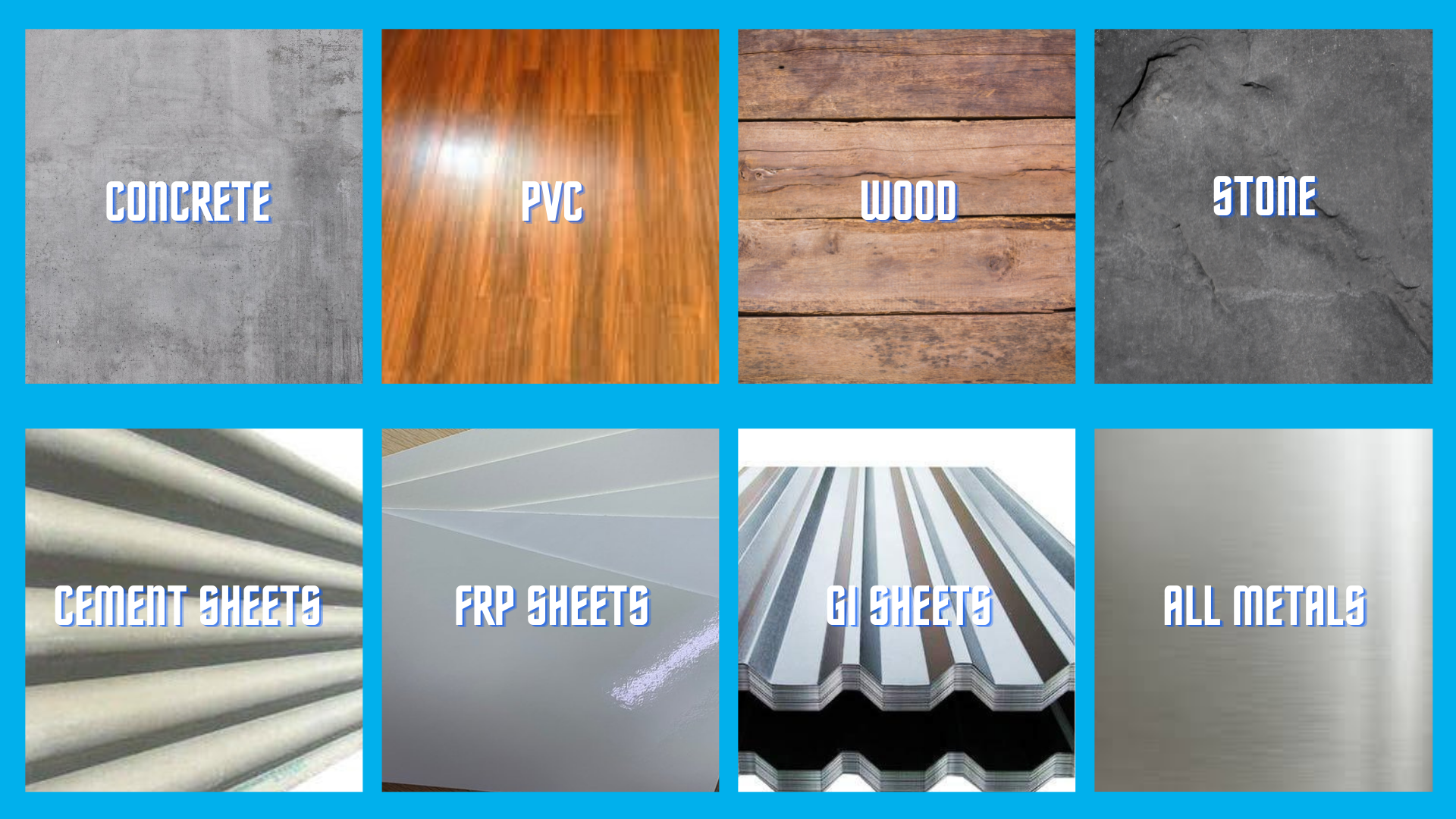

Direct Application on Following Surfaces

USPs of Elastoroof PU

- Single Component Liquid Coating

- Forms Seamless Rubberized Membrane When Cured

- Elongation of 700%

- Applied Indoors and Outdoors

- Cold Applied by Brush, Squeegee, or Spray Equipment

- Conforms to European Code DIN 1048 and American Code ASTM C 386

Easy To Apply Without Any Training

PREPARE THE SURFACE

Free the surface to be coated of all foreign matter, dirt, dust, paint, oil, grease, etc. using stiff nylon or steel bristled brush.

Final surface preparation should be done by mechanical means using a floor polishing machine or equivalent abrasive cleaning methods.

Clean it further using compressed air.

Fill all voids, cracks, and level all irregular surfaces with polymer modified repair mortar.

Allow it to cure for at least 24 hrs.

Cure freshly placed concrete for at least 7 days before applying ELASTOROOF PU.

Final surface preparation should be done by mechanical means using a floor polishing machine or equivalent abrasive cleaning methods.

Clean it further using compressed air.

Fill all voids, cracks, and level all irregular surfaces with polymer modified repair mortar.

Allow it to cure for at least 24 hrs.

Cure freshly placed concrete for at least 7 days before applying ELASTOROOF PU.

PRIME THE SURFACE

Prime the surface using SUNPRIME PU.

Open the container and mix SUNPRIME PU thoroughly using a slow-speed drill type stirrer to get a uniform consistency.

For horizontal and vertical surfaces, apply a thin coat of SUNPRIME PU by brush. Airless spraying equipment may also be used.

Ensure that no excess liquid collects on the edges of the floor.

If this occurs, spread the liquid evenly by brush. Air cure for 30 mins hours before applying 1st coat of ELASTOROOF PU.

Open the container and mix SUNPRIME PU thoroughly using a slow-speed drill type stirrer to get a uniform consistency.

For horizontal and vertical surfaces, apply a thin coat of SUNPRIME PU by brush. Airless spraying equipment may also be used.

Ensure that no excess liquid collects on the edges of the floor.

If this occurs, spread the liquid evenly by brush. Air cure for 30 mins hours before applying 1st coat of ELASTOROOF PU.

COAT THE SURFACE

ELASTOROOF PU liquid-applied membrane can be directly applied to the primed concrete surface provided that the concrete is in good, sound condition.

We recommend that for this type of application 1.5 kg per sqm be applied and that liquid-applied membrane be applied in two coats.

The first coat of ELASTOROOF PU liquid-applied membrane should be applied by brush, roller, airless spray, or squeegee to all surfaces @ 1 kg/sq m.

The ELASTOROOF PU liquid-applied membrane should then be allowed to cure until ‘tack free’. It is recommended that ideally this be left overnight.

The second coat of ELASTOROOF PU liquid-applied membrane should be applied by brush or squeegee to all surfaces @ 0.5 kg/sq m.

It is recommended that this second coat be applied at right angles to the first.

While the 2nd coat has significantly cured(hardened), but it is yet slightly tacky, sand may be sprinkled to provide a key for the subsequent protection screed.

The ELASTOROOF PU liquid-applied membrane should be allowed to cure for minimum of 12 - 48 hours depending on ambient conditions.

We recommend that the liquid-applied membrane be protected with a cement-sand dash coat, prior to laying any tiles/other surfacing.

We recommend that for this type of application 1.5 kg per sqm be applied and that liquid-applied membrane be applied in two coats.

The first coat of ELASTOROOF PU liquid-applied membrane should be applied by brush, roller, airless spray, or squeegee to all surfaces @ 1 kg/sq m.

The ELASTOROOF PU liquid-applied membrane should then be allowed to cure until ‘tack free’. It is recommended that ideally this be left overnight.

The second coat of ELASTOROOF PU liquid-applied membrane should be applied by brush or squeegee to all surfaces @ 0.5 kg/sq m.

It is recommended that this second coat be applied at right angles to the first.

While the 2nd coat has significantly cured(hardened), but it is yet slightly tacky, sand may be sprinkled to provide a key for the subsequent protection screed.

The ELASTOROOF PU liquid-applied membrane should be allowed to cure for minimum of 12 - 48 hours depending on ambient conditions.

We recommend that the liquid-applied membrane be protected with a cement-sand dash coat, prior to laying any tiles/other surfacing.

Packaging

Elastoroof PU is available in 25 Kg containers.

Our Clients